Fuels

PetrolDiesel

Biofuels

Natural Gas

Propane

Fossil fuels continue to be used as the primary fuel source for transportation. In some regions, non-petroleum fuels play an increasingly significant role, such as biofuels blended with petroleum fuels in Brazil.

The importance of combining cleaner vehicles with clean fuels is also discussed in the Tools introduction.

Petroleum offers a number of benefits which make it likely to continue to dominate the fuels market for the near to medium term.

Ideally, the perfect fuel appropriate for use in private cars should satisfy the following characteristics:

- Energy dense for maximum range;

- Easily storable and transportable;

- Stable over wide range of temperatures;

- Non-damaging to car engine;

- Inexpensive to produce and distribute;

- Available from secure sources;

- Not detrimental to air quality;

- Low CO2 over its life cycle.

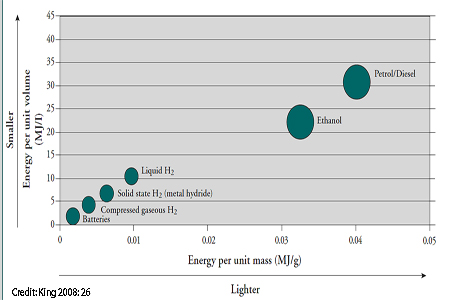

Energy density of a fuel is an important issue when considering the viability of certain fuels for vehicle use. Two important aspects to consider are :

- Energy contained in a given mass, which determines the range a vehicle can get with a given fuel, and;

- Energy stored in a given volume of fuel higher volume-energy density means less space is require to store the fuel in the vehicle, which can result in less space needed for a fuel storage facility on the vehicle.

The following graph compares energy density of a variety of fuels, and illustrates that petrol and diesel, and to a lesser extent ethanol, are good fuels for use in personal vehicles.

Illustrative energy density of some fuel types

The following discussion will look at a variety of different fuels, each with its own benefits and drawbacks, although none will completely satisfy the list above. There will always be tradeoffs between the different elements of what constitutes a perfect fuel.

Petrol

For petrol vehicles, unleaded petrol (gasoline) should be used. Unleaded petrol is better for the engine, eliminates emissions of lead particles, and enables the use of a catalytic converter for further emissions reductions.

All vehicles can run on unleaded petrol: the claim that some vehicles need leaded fuel is not true. Modern fuels with the right octane rating are better for engines; in addition, use of unleaded petrol results in less wear and tear on other vehicle components, such as the exhaust system. For very old cars (pre-1978), there was a legitimate concern that piston valve seats might be damaged if using unleaded petrol. However, this turned out to be much less of a problem than first anticipated. Unleaded petrol is now the standard in virtually every country around the world – world map available here.

Diesel

Low-sulphur diesel contains less than 500 ppm (parts per million) of sulphur. Sulphur levels as high as 5,000 to 10,000 ppm can be found in some places in the world. In Japan, Republic of Korea, parts of Europe (such as in Scandinavia and Germany) and in some parts of the US, diesel with sulphur levels as low as <15 ppm is currently used.

Using low-sulphur diesel has a number of benefits, such as: decreasing emissions of sulphur oxides (SOx) and fine particles (PM2.5); extending engine life; and enabling the use of emission control technologies.

To maximize reduction of various emissions, diesel engines with advanced technology should be combined with very low sulphur diesel fuel (15 ppm). These modern engines use very high pressure (2,000- 29,000 psi) common-rail injector systems which reduce emissions. These engines emit very low levels of nitrogen oxides and particulate matter, when equipped with a particulate trap.

Diesel engines are an important technology for near-term efficiency improvements. However, without stringent conventional pollutant emissions standards, requiring diesel particulate filters, diesel vehicles will have much higher emissions of particulate matter (PM), mostly eliminating their climate benefit and causing a significant negative impact on air quality and human health. Ultra low sulfur diesel (10-15 ppm sulfur) is required for diesel particulate filters to function. Advanced emissions controls, introduced in Europe only very recently and required in the U.S. since 2007, are necessary to bring both PM and NOx emissions close to the level of clean gasoline cars, in order to eliminate potentially serious health impacts of diesel vehicles.

In a study of similar pairs of diesel and gasoline vehicles sold in the EU, Euro 3 and 4 diesel vehicles without particulate filters had much higher PM emissions. When using a 20-year GWP for black carbon of 1600 (range of literature values are between 480 to 3200), the climate benefit of diesel vehicles was only 3% on a CO2-equivalent basis.

Comparison of like pairs of gasoline and diesel vehicle models

Attribute |

Gasoline vehicles |

Diesel vehicles (without DPF) |

Difference |

Curb weight (kg) |

1452 |

1500 |

48kg |

Fuel economy (km/L) |

11.5 |

16.2 |

+41% |

CO2 emissions (g/km) |

205 |

169 |

-18% |

PM emissions (g/km) |

-- |

0.022 |

0.022 |

CO2e emissions (g/km) |

205 |

201 |

-3% |

Use of diesel technology would be incentivized under any form of standard but some standard designs would provide a greater incentive than others. Weight-based standards would give greater preference to diesels than footprint-based. And fuel economy standards provide a greater diesel incentive than CO2 or GHG standards. Stringent, fuel-neutral conventional pollutant standards are necessary to ensure that air quality, health, and climate goals are not compromised by more efficient but higher polluting diesel vehicles.

Potential fuel economy benefit [30-40%]

Biofuels

The use of biofuels is currently a contentious issue. Feedstock of biofuels is a very important consideration when considering the CO2 emissions from the generation of biofuel. Deforestation is often promulgated by crops destined for biofuel production, a trend which mitigates any reduction in transport-related CO2 emissions. Currently, biofuel production demands high amounts of arable land, and risks diverting crops from food production to biofuel use, which would increase global food prices if widespread. It is therefore imperative that too much emphasis is not put into biofuels in the near term, as this could be counter-productive, putting the world’s environmental resources (ie. forests and arable land for food production) under pressure. However, there is potential for biofuels to have a positive effect on CO2 emissions from the transport sector. The International Energy Agency released a Technology Roadmap on Biofuels for Transport in 2011.

Biofuels are made from biomass such as plants or organic waste, and can be used in low concentration blends (5-10%) with petrol or diesel without engine modification and in high concentrations (85-100%) with specially adapted vehicles. Biofuels generally have a lower energy density than petroleum fuels, resulting in a lower range in a higher blend fuel. Biodiesel and ethanol are the two most common biofuels.

For a more inclusive discussion on biofuels, please refer to The King Review of Low Carbon Cars

Biodiesel

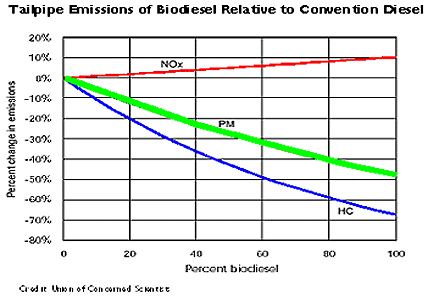

Biodiesel is a non-toxic, biodegradable fuel made from vegetable oil, waste cooking oil, animal fat or fish oil, and is produced from a process called transesterification in which methanol and sodium hydroxide are mixed with oil, producing biodiesel. Biodiesel can offer distinct environmental advantages over petroleum diesel fuels. When blended with diesel fuel, emissions of tailpipe pollutants associated with conventional diesel are reduced. However, use of biodiesel may result in greater emissions of smog-forming nitrogen oxides.

Biodiesel can be used in all diesel-fuelled vehicles. Some vehicles (built since 1994) may be able to use 100% biodiesel, though many vehicles require some engine modification, such as replacing the rubber fuel hoses and fuel pump seals with a compatible elastomer.

Biodiesel is still costly to produce currently, it is 1.5 to 2 times more than ordinary diesel. The price of biodiesel is dependent upon feedstock prices (i.e. rapeseed, sunflower, or soybeans). The total amount of feedstock available for biodiesel production is limited due to land constraints and economic reasons; therefore biodiesel is seen as a future niche fuel or low-blending fuel. Current biodiesel production is dependent on government subsidies and regulations, such as the EU Renewable Fuels Directive.

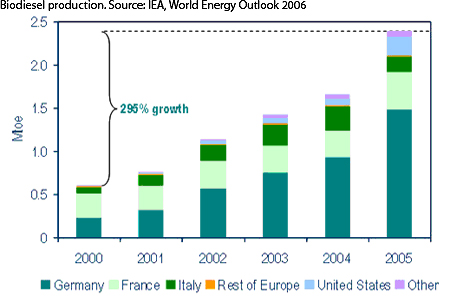

Figure 11: Biodiesel production. Source: IEA, World Energy Outlook 2006 Biodiesel production has almost quadrupled since 2000, with European countries - notably Germany - contributing most of the growth

Second Generation Biodiesel

High quality, diesel-compatible fuel and even jet fuel can be produced by hydrocracking vegetable oil and animal fats a technology that is fully commercial. Despite the advances of hydrocracking and higher quality biofuels derived from the process, it still does not alleviate the issue of feedstocks being in competition with food, the potentially high feedstock prices and typically low-yields. However, second generation biodiesel and biofuels can be made from feedstocks like wheat straw, corn stover and wood residues from forestry operations and pulp and paper making- essentially any type of biomass including wood and other cellulose-based materials. These feedstocks can be grown on marginal land not in use for food production, and from short-rotation forests such as fast-growing willow or poplar trees. Other potential feedstocks include manure and municipal solid waste.

Ethanol

Ethanol can also be used to fuel motor vehicles either at 100 percent or with some mixture of petrol, which helps starting in cold weather. While ethanol in the U.S. is made from corn, which is only supported by price subsidies, in Brazil, ethanol is made from the waste from the sugar cane, which results in a much lower cost. In the U.S. some cars are designed to use anywhere from 100 percent petrol to 85 percent ethanol. These cars adjust their calibration depending on the mix of the fuel and are known as flex-fuel vehicles.

Ethanol has been used as a motor fuel since cars were first manufactured. It is a fuel well-suited for petrol engines; it has a clean combustion process resulting in lower emissions of particulate matter, hydrocarbons and carbon monoxide. The greatest benefit of using ethanol is the potential for CO2 emissions reductions (based on life-cycle emissions). Drawbacks include reliance on subsidies (in some cases), and a potential resultant increase in food prices and deforestation (in certain cases).

Ethanol is an alcohol that is liquid at ambient temperature and pressure, and is in wide use in many countries throughout the world as a fuel. It can be used in blends with gasoline in existing vehicles with little or no modification to the internal combustion engine. Ethanol is a clean, high-octane fuel although its energy density is only about 65% that of gasoline and its use as a blend tends to lower nitrogen oxide (NOx) emissions.

Ethanol, generally, has had penetration into the fuel market as a small percentage in petrol and diesel fuel blends, such as 10% ethanol and 90% gasoline. Higher level blends of up to 85% ethanol can be found in countries such as Sweden and in parts of the US. In Brazil, most vehicles are capable of running on any blend of ethanol and gasoline, which is sold with an ethanol content of 20-25%.

All petrol vehicles can use petrol that has been blended with up to 20% ethanol without any problems. To convert a conventional spark-ignition engine vehicle to run on pure bio ethanol requires the adjustment of the ignition timing, and the fitting of a larger fuel tank due to the fuel's low energy density. As alcohol fuels degrade certain types of rubber and accelerate the corrosion of several metals, some engine components may also need to be replaced.

The so called Flexible Fuel Vehicles (FFV) can run on conventional petrol but also on blends with a higher percentage of ethanol (up to 85%) these are highly efficient and produce lower emissions.

Ethanol from corn has been produced mainly in the US since the 1970s. In order to be competitive, ethanol production from corn is heavily dependent on subsidies, and therefore is not considered a long-term solution for replacing petrol. Benefits of CO2 emissions reduction are partly offset by the energy-intensive production process needed to produce ethanol, although fuelling a vehicle with corn-based ethanol will still reduce CO2 emissions by 20-30% on a-life cycle basis, compared with petrol use.

Ethanol from grain has been produced mainly in Europe for a number of years. But, as with ethanol from corn, it is highly unlikely that ethanol from grain will ever become competitive and a long-term solution, because of heavy subsidies. CO2 emissions reductions from fuelling a vehicle with ethanol from grain are approximately 30-40% on a life-cycle basis, compared with petrol use.

Brazil is currently the major producer and exporter of ethanol from sugar cane. With the current petrol prices, ethanol from sugar cane is fairly competitive; the cost of ethanol from sugar cane is approximately half of that of ethanol from grain or corn. CO2 emissions reductions from fuelling a vehicle with ethanol from sugar cane are estimated to be 50-90% on a life-cycle basis, compared with petrol use.

Second Generation Ethanol

Second generation ethanol entails the use of materials left over from conventional ethanol production the large quantities of fibrous remains from the feedstock, such as seed husks and stalks. Use of much greater types of organic material for ethanol production will allow a variety of non-food crops that can be grown for ethanol production and which do not compete with food production, such as waste materials and crops such as grasses and trees. In North America, this includes maize stalks and other grain straws, and in Europe attention is focused on food-processing waste, grass and wood crops. Despite a plethora of potential feedstock and improvements in the refining process, no commercial scale conversion facilities have yet to be built.

Natural Gas

Natural gas can be used as an alternative fuel for vehicles. It burns more cleanly than gasoline or diesel, produces fewer toxic pollutants and can also reduce life-cycle GHG emissions by around 20%, compared with pure gasoline. In Canada, natural gas is currently less expensive than gasoline as a transport fuel, on an energy content adjusted basis, due to a lack of excise tax or provincial/territorial road tax on natural gas as a vehicle fuel. For more information, visit the Canadian Natural Gas Vehicle Alliance’s Website.

Propane

Propane can be used in certain vehicles as a transportation fuel, where it is pressurized and stored as a liquid. Propane burns more cleanly than petrol or diesel, and can reduce life-cycle GHG emissions by around 20% compared with pure gasoline. Propane has a low sulphur content, and does not produce significant amounts of sulphur oxides, which can contribute to acid rain and smog. A draw back to propane, and one common with biodiesel, ethanol and natural gas, is the lower energy content by volume than gasoline, with 1.4 litres of propane required to travel the same distance as one litre of gasoline.